鑽石線(鑽石切割線)

Name:鑽石線(鑽石切割線)

Model:HC-SHL03

Unit:PCS

Specification(Grade):HC-SHL03

Price:USD 0.000

Member:Please login member thanks

Goods detail informatio

※ Main features:

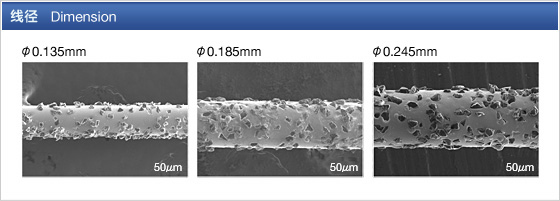

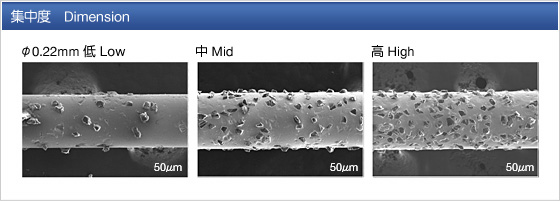

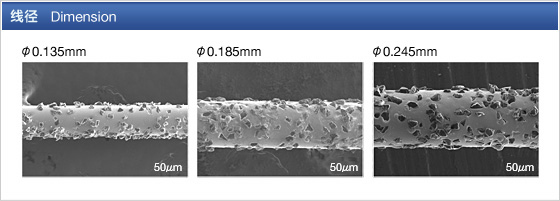

※ Diamond wire types:

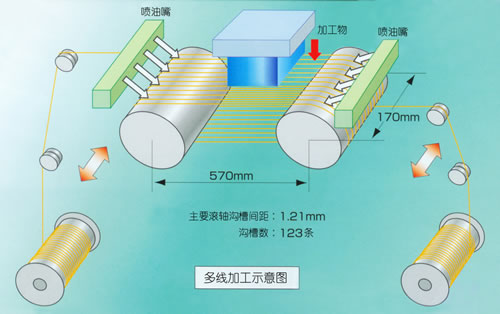

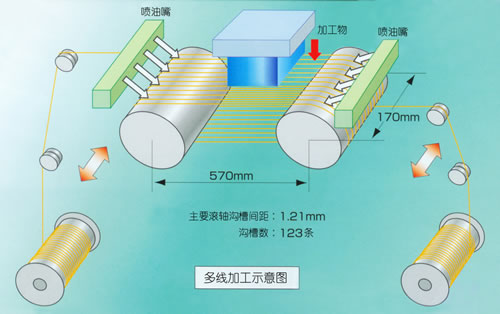

※ Machining schematic diagram

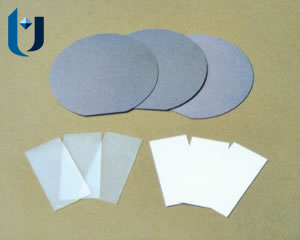

※ Machining examples

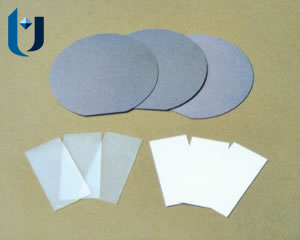

The above figure demonstrates silicon, glass, and aluminum products which had been cut. This cutting wire can be widely used for the cutting of precision materials such as sapphire, silicon rod, quartz glass, silicon, aluminum sheet, etc.

Machining conditions for φ2 inches

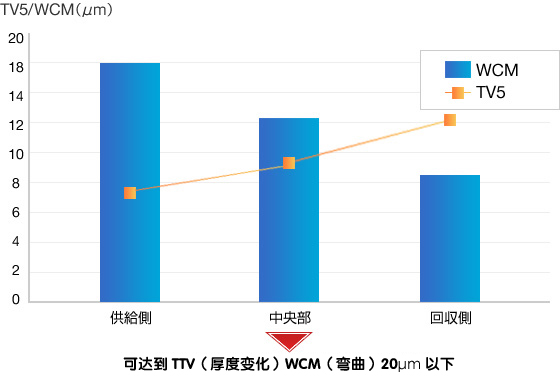

φ2 abrasion sapphire machining accuracy result

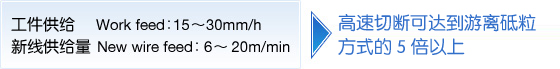

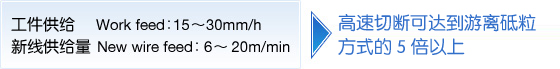

Compared with free abrasive grain machining, more than 5 times of high-speed cutting can be achieved.

|

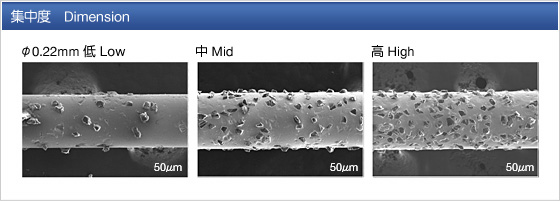

●Can achieve high-speed cutting machining Compared with free abrasive grain machining method, more than 5-10 times of high-speed cutting machining can be achieved. (2-5 times more than resin series fix abrasive grain machining method) ●Can conduct high precision machining Diamond wire has high stability, can conduct high precision machining. ●Combination of materials Because it is metal binder material, no restriction on liquid type when machining. ●Concentration of abrasive grains can be highly controlled Can control the degree of concentration of abrasive grains. ●Long-life construction Abrasive grains give prominence to higher (compared with the company’s product before: increased by 50%) long-life construction. |

|

※ Diamond wire types:

※ Machining schematic diagram

※ Machining examples

The above figure demonstrates silicon, glass, and aluminum products which had been cut. This cutting wire can be widely used for the cutting of precision materials such as sapphire, silicon rod, quartz glass, silicon, aluminum sheet, etc.

| Profile (mm) | Average φ0.245 | Average φ0.245 | |

| Type | Abrasive grain # | #500 | #500 |

| Workpiece | Material | Sapphire | Aluminum oxide (99.9%) |

| Size (mm) | φ2"x L100 | φ2"x L200 | |

| Cutting conditions | Wire speed (m/min) | MAX600 | MAX600 |

| Workpiece feed speed (mm/h) | 24 | 15 | |

| Wire tension (N) | 35 | 35 | |

| Machining liquid | Water-soluble machining liquid | Water-soluble machining liquid | |

| Cut result | Surface roughness Ra(?m) | 0.17 | 0.15 |

| Curvature /SORI(?m) | 19.3 | 12.7 | |

| Thickness variation TTV5 (mm) | 0.018 | 0.010 | |

| Average thickness (mm) | 0.753 | 0.751 |

Machining conditions for φ2 inches

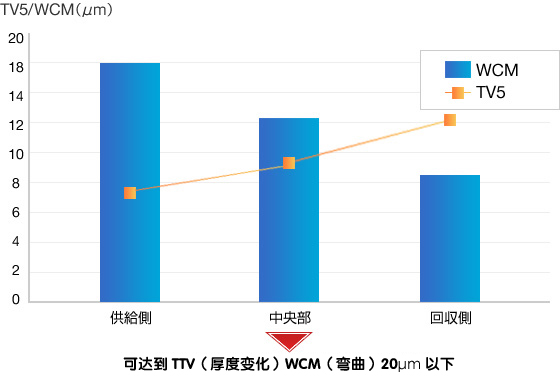

φ2 abrasion sapphire machining accuracy result

Compared with free abrasive grain machining, more than 5 times of high-speed cutting can be achieved.